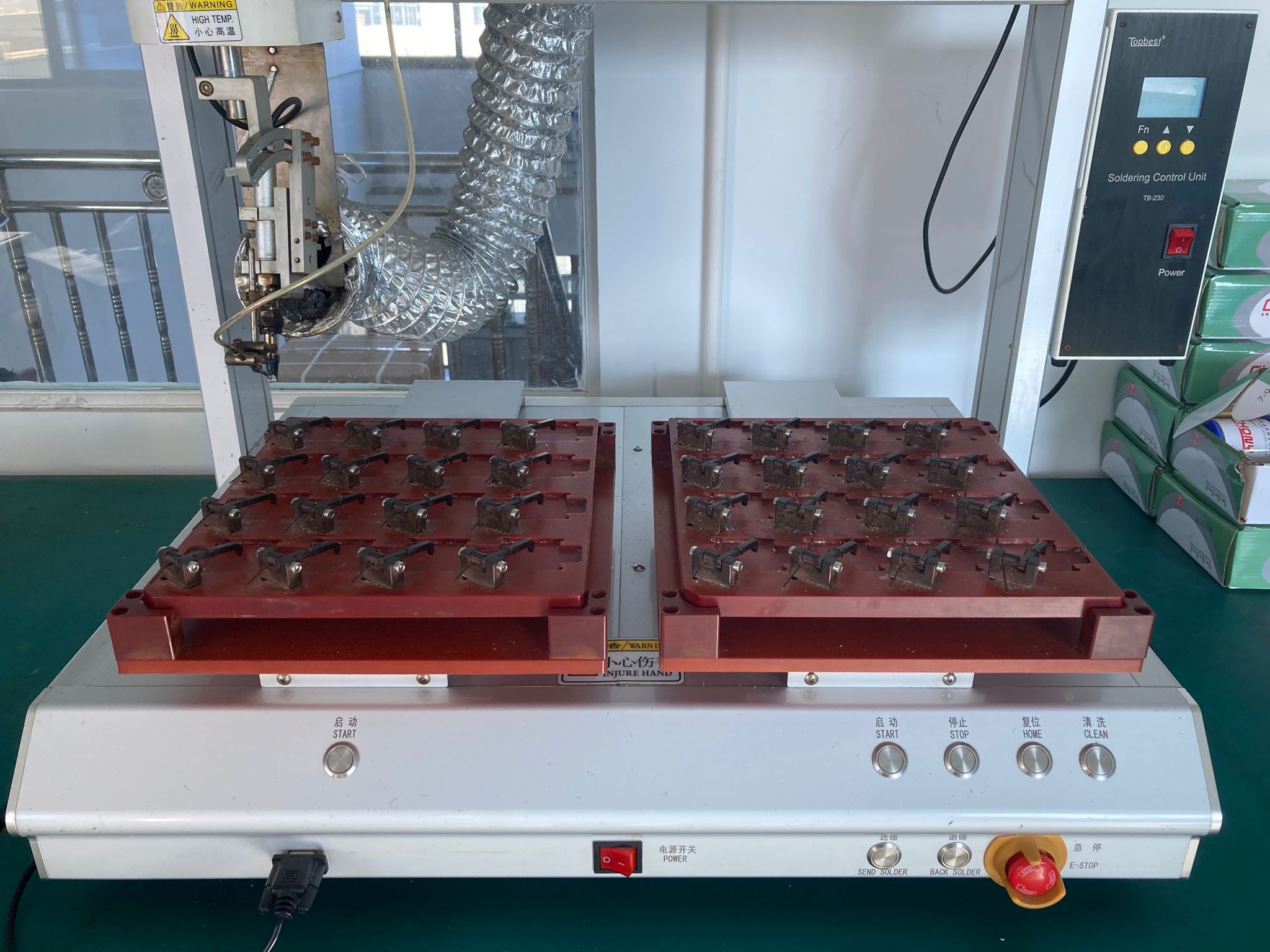

The soldering process is to use the melting of metal tin to fill the connection gap between two metal objects to ensure that the two metal objects are connected as a whole, and to maintain the firmness and conductivity of the connection between the two metal objects. The stability of the soldering process is closely related to the relevant process parameters in the soldering process, mainly including the following key factors: 1. The material properties of the welding surface of metal parts; 2. Cleanliness of the welding surface; 3. The amount of solder (the amount of solder); 4. Welding temperature 5. Welding time. The material properties of the welding surface of metal parts and the cleanliness of the welding surface can be effectively controlled by the product structure design. In conventional manual soldering, the three factors of solder quantity (solder volume), soldering temperature, and soldering time can only be achieved by the operating skills of the soldering operator. Using operating experience to determine the quality of soldering can only be carried out with fuzzy qualitative control. The welding quality is affected by the technical level of the operators and the fluctuation of mood factors, and there will be certain fluctuations. Product defects caused by welding defects account for a large proportion of the cause statistics of product quality problems. Therefore, the use of automatic welding processes can reduce the amount of solder (the amount of solder) in the welding project, the welding temperature, and the welding time. The factors are improved from artificial fuzzy qualitative control to intelligent quantitative control. It is a very necessary measure to ensure the consistency and stability of the welding quality of the welded parts. Since 2019, Tor Electric Company invested funds to reform the welding production process, changed the welding of conductive parts in SPD production from manual welding to automatic welding machine welding, and increased the qualification rate of SPD products from 95% to 99.5%. The trouble-free working time is increased by 30%, which provides a good technological basis for the production of SPD products with stable quality.

The soldering process is to use the melting of metal tin to fill the connection gap between two metal objects to ensure that the two metal objects are connected as a whole, and to maintain the firmness and conductivity of the connection between the two metal objects. The stability of the soldering process is closely related to the relevant process parameters in the soldering process, mainly including the following key factors: 1. The material properties of the welding surface of metal parts; 2. Cleanliness of the welding surface; 3. The amount of solder (the amount of solder); 4. Welding temperature 5. Welding time. The material properties of the welding surface of metal parts and the cleanliness of the welding surface can be effectively controlled by the product structure design. In conventional manual soldering, the three factors of solder quantity (solder volume), soldering temperature, and soldering time can only be achieved by the operating skills of the soldering operator. Using operating experience to determine the quality of soldering can only be carried out with fuzzy qualitative control. The welding quality is affected by the technical level of the operators and the fluctuation of mood factors, and there will be certain fluctuations. Product defects caused by welding defects account for a large proportion of the cause statistics of product quality problems. Therefore, the use of automatic welding processes can reduce the amount of solder (the amount of solder) in the welding project, the welding temperature, and the welding time. The factors are improved from artificial fuzzy qualitative control to intelligent quantitative control. It is a very necessary measure to ensure the consistency and stability of the welding quality of the welded parts. Since 2019, Tor Electric Company invested funds to reform the welding production process, changed the welding of conductive parts in SPD production from manual welding to automatic welding machine welding, and increased the qualification rate of SPD products from 95% to 99.5%. The trouble-free working time is increased by 30%, which provides a good technological basis for the production of SPD products with stable quality.

Post time: May-28-2023